|

Second Floor |

On this floor, the central task involving heat was starching and ironing. Extreme heat was generated not just by hand irons, but also by mechanical pressers and special steam devices made to deal with collars, cuffs, shirts, shirtwaists, etc. For this reason, there are purpose-built high ceilings and huge windows.

|

|

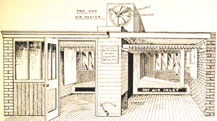

A

plan for "twin dry rooms"

|

This floor also housed the steam laundry's drying room. Its four small, low windows were clearly visible from the outside. Until 1999, when two were destroyed, these windows remained true industrial rarities. Ceilings here are 14' from bottom of beam to floor.

The second floor’s wooden beams measure 8" x 20", they run North/South and are separated by only 5'. Every 15', a 12" square wooden post aligns with the center East/West beam which runs the length of the building.

At least

one-quarter of the second floor beams, however, are reinforced on both

sides with two 15' long 3" x 12" wooden planks. These are bolted

to the sides of the beams in an A-frame style.

Until J.C. Hagen purchased DC Keeney's laundry business, this was the top floor of the working laundry. As Sanborn maps and a Department of Buildings Permit (#227730) show, the third floor was used for storage until 1923 when, John C. Hagen purchased Keeney’s laundry business. He enlarged heat-generating operations to the entire building and cut two openings in the ceiling of this floor to form clothes chutes (Permit #224814).